In the age of environmental consciousness, biodegradable containers for food have become a sustainable alternative to traditional packaging. These eco-friendly food containers not only help reduce plastic waste but also contribute to a healthier planet. If you're wondering how these biodegradable containers are made, you're in the right place. In this article, we'll take a deep dive into the fascinating world of crafting biodegradable containers for food.

The Biodegradable Containers for Food Begins with Natural Materials

To create biodegradable containers for food, we embark on a journey that starts with natural materials. Unlike conventional plastic containers, which are derived from fossil fuels, biodegradable containers are made from renewable resources. One of the key ingredients in crafting these eco-friendly marvels is molded fiber pulp.

Molded fiber pulp is a versatile material that is derived from natural sources like wood pulp, bamboo, sugarcane, and even recycled paper. This sustainable sourcing of materials ensures that the containers are not only biodegradable but also compostable, meaning they can be returned to the earth and enrich the soil.

The Pulp Formation Process of Biodegradable Containers for Food

The next step in creating biodegradable containers for food involves the pulp formation process. Here, the chosen natural materials are broken down into fibers through a series of mechanical and chemical processes. These fibers are then mixed with water to create a pulp mixture. The beauty of this process is that it doesn't rely on harsh chemicals or toxins, making it safe for both consumers and the environment.

Once the pulp mixture is prepared, it's time to give it shape. Various molds and dies are used to mold the pulp into the desired container shape. The burstiness of this step is evident in the versatility of shapes and capacities available, from soup bowls to containers of different sizes and forms. The process ensures that biodegradable containers can cater to a wide range of food types and serving needs.

Strengthening for Practical Use Biodegradable Containers for Food

While biodegradable containers for food are eco-friendly and compostable, they also need to be functional and durable. This is where the strengthening process comes into play. To ensure these containers can withstand the rigors of handling food, they undergo a pressing and drying process that enhances their structural integrity.

The perplexity of this step lies in the various techniques used to strengthen the containers. Some containers may be treated with a natural water-resistant coating to prevent sogginess when in contact with liquids. This makes them ideal for soups, salads, and other dishes that contain moisture.

Additionally, some containers may undergo a baking process to give them extra rigidity. The burstiness here is the adaptability to cater to different food types. For instance, containers designed to hold hot and greasy foods are crafted to be more robust, while those meant for cold salads maintain a different composition.

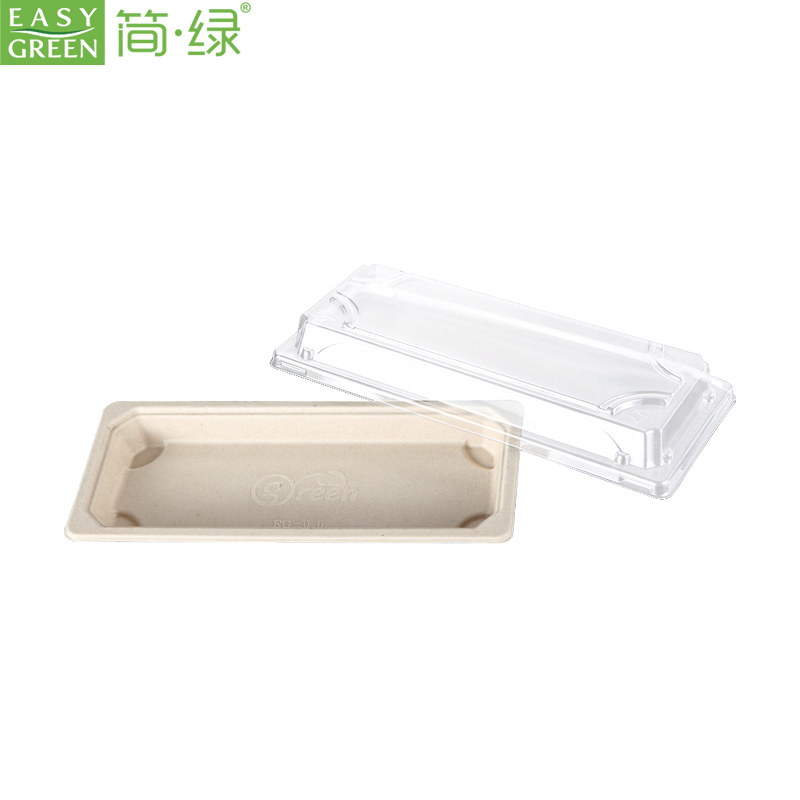

Transparency in the Biodegradable Containers for Food's Lids

In the world of biodegradable food containers, the lid is just as important as the base. Clear anti-fog transparent lids are an ingenious addition that allows consumers to see what's inside the container without having to open it. This transparency serves two purposes: it enhances the presentation of the food and helps prevent unnecessary handling, keeping the contents fresh and hygienic.

These lids are typically made from biodegradable plastics, such as PLA (Polylactic Acid), which is derived from renewable resources like cornstarch. The burstiness here comes from the fact that biodegradable containers for food provide consumers with the best of both worlds - a clear view of their meal and an environmentally friendly packaging solution.

For those who are interested in incorporating biodegradable containers into their food business, there are wholesale options available. Easy Green, for instance, offers a range of eco-friendly food containers for wholesale purchase. These containers are not only biodegradable but are also customizable, allowing businesses to brand their packaging with their logos and designs.

English

English